The Junkers

Ju-88 A-5 was a multitask warplane which entered service in time to participate

on the “Blitz”, and went on soldiering with the Luftwaffe on the principal theatres

of action during WWII. It appeared before the A-4 model. The A-5 featured the

fuselage of the A-1 coupled with extended wings and at some point, different

versions of the famous Jumo 211 power plant.

This

modelling experience started with a nice little surprise. ICM chose to pack the

256 plastic parts supplied inside a very sturdy cardboard box. The very nice

box cover was printed separately in glossy cardboard and covered the top and

sides of the main box. This approach ensured a perfect protection of the

plastic components of the kit against the adventures of transit and handling of

such a box. On the same tone, the 20 clear plastic parts were protected inside

a separate plastic bag and the decal sheet, which catered for four colour

options was also well protected.

Upon the

examination of the plastic parts and the consultation of several reference

sources and internet sites, several shortcomings of this kit became apparent.

One of the major criticism to this kit was the inaccurate cockpit floor, which

lacked a very noticeable raised platform. There is already a correction resin

kit for it, available from AIMS products, but it was decided to make the most

of the kit parts, coupled with Eduard photo-etched metal details and home-made

details. At the end of the day, and with the canopy attached, this modeller can

live with that easily. On the same tone, there were several panel lines that

needed correction, as well as several sink marks on the fuselage surface.

Neither of these glitches are deal-breakers. They were corrected with ease and

without spending much time.

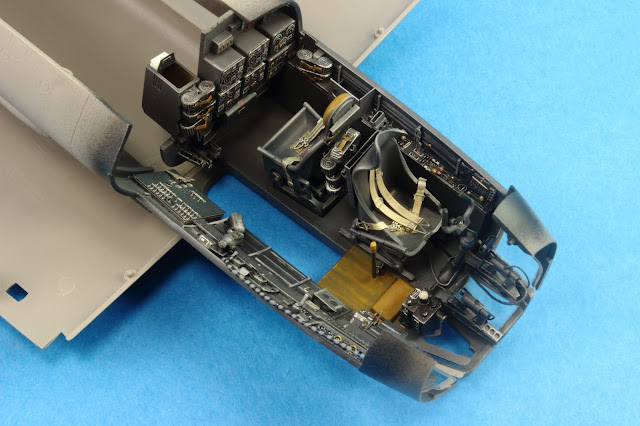

To address

some glitches and to enhance even further the already good plastic parts,

Eduard 49750 interior and 48876 exterior photo etched frets were employed were

deemed necessary or advantageous.

Before glue

was committed to plastic, the instructions were scrutinised and compared with

the Eduard instructions sheets. This step was very important, as it allowed for

a concise and workable build sequence including both plastic and photo etched

detail parts.

Before

the application of RLM 66 Schwartzgrau, the cockpit was embellished with

Eduard`s photo-etched metal parts.

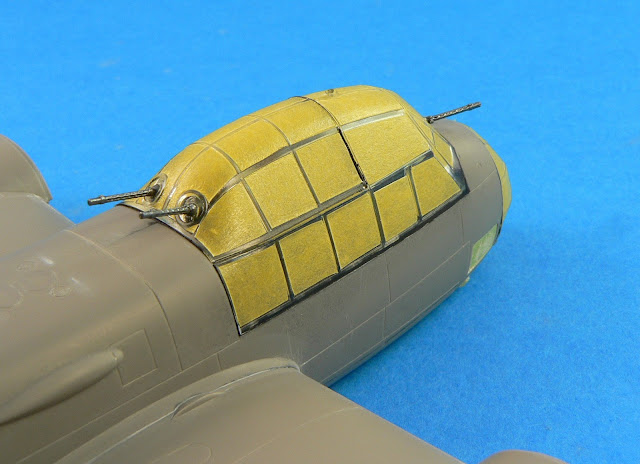

The

radiator faces were detailed with photo-etched mesh and surface details. These

catered for a shortcoming of the kit.

In

order to enhance the scale effect, the exhaust stacks were drilled open.

The landing

gear legs also received some attention from the Eduard PE fret. In addition,

small disks of styrene were produced with a punch&die set and used to

detail the kit parts.

The cockpit

parts were given a black primer coat followed by RLM 66 Schwartzgrau. A lighter

shade of this colour was sprayed on several panels to add interest.

The

complete cockpit with plastic, photo-etched and scratch built pieces surely looks

busy:

The ventral

gondola was detailed with plastic pieces and wire. Sadly, the inner masks were

forgotten inside the model. One can only pretend they`re curtains…

The engines

and both nacelles were detailed with photo etched parts and sections of plastic

and hypodermic needles.

The wing to

fuselage seam only needed a smear of Mr. Surfacer 500 later cleaned up with a

cotton bud damp in Tamiya Lacquer thinner.

Priority

was given to the joint between upper wing half and fuselage. The gap that

resulted between both wing halves was far easier to fill with superglue and

sand to shape.

The fit of

the clear parts was very good. Note the MG`s already in place. Strangely they

survived until the end of the build.

The

engines were painted black, the details picked up with various acrylic paints

and the edges drybrushed with Oily Steel.

Some care

was needed with the engine nacelles. Sink marks had to be treated and the hot

air exhaust ducts removed and drilled to backdate them for the earlier A-1

style present on the A-5 airframes.

The port

engine was to be displayed with opened maintenance panels. The plastic parts

were sliced to make way for the photo etched replacements provided by Eduard.

Note the drilled out hot air exhausts.

The starboard

engine nacelle proved very problematic. The top panel was skinned with 10thou

plasticard and the edges filled with Mr. Dissolved Putty. All this was sanded

and feathered to shape with various grades of sanding paper.

The canopy frames were first painted with RLM 66 before the main colour was

applied. Note the engine nacelles with the surfaces regularized.

Vallejo Model Air 71255 RLM65 was used on the undersides. The paint

was applied highly diluted to allow the black primer to show through.

On the upper surfaces the first colour to be applied was Vallejo Model Air

71015 RLM 71 Dark Green. This was also applied in a way to permit the black to

show through.

Tamiya masking tape was used to define the areas that were painted RLM 70

black Green. Vallejo Model Air 71021 was the shade chosen.

The decals performed well under the usage of Micro Set and Sol

solutions. After allowing a couple of days for the decals to dry, the fuselage

was washed with soapy water and sealed with another gloss coat.

Ammo

from Mig Jimenez 1608 Dark Green Grey emphasised the panel lines on the upper

surfaces. Again, a flat brush made the cleaning work and created a nice patina.

Com.Art`s 21041 Old Oil and 20021 Transparent Smoke were mixed and

airbrushed on the main structural panel lines.

The oil dot filter technique was employed on the entire surface of the model.

Over a satin surface, oil paint dots were added and blended with a brush moist

on odourless white spirits.

Both exhaust gases and oil trails were replicated with oil paints. The colours

used were mainly Burnt Umber and Lamp Black.

Finished model